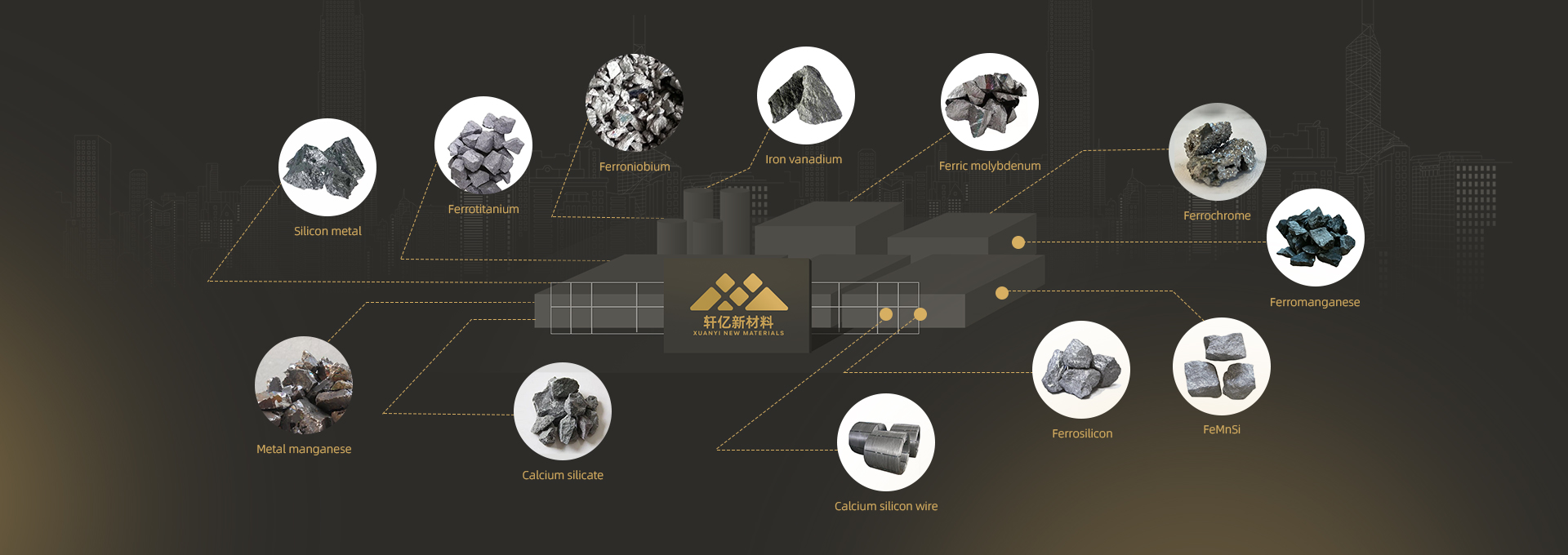

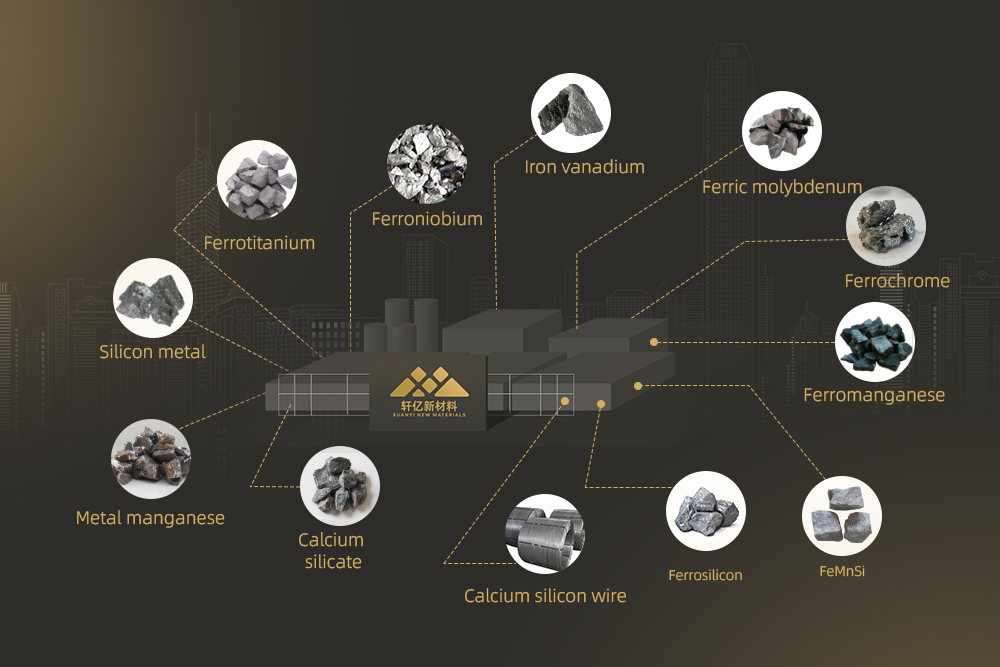

Ferrovanadium

Calcium silicon zinc wire

Ferrochrome

Silicon manganese

Ferrosilicon

Silicon Metal

Manganese metal

Ferromanganese

Ferrotitanium

Iron-Molybdenum

Iron and Niobium

Manganese Ore

Calcium silicon core wire

Calcium silicon wire is an additive in steelmaking, which is beneficial to adjust and control the content of easily oxidized elements and trace elements, can significantly increase the alloy yield, reduce smelting costs, shorten smelting time, and accurately control the composition.

Low carbon ferrochrome

Ferromanganese is an indispensable deoxidizer and desulfurizer in the steelmaking industry.

Silicon manganese 6818

Introduction to Basic Knowledge of Silicon Manganese Alloy Introduction to Basic Knowledge of Silicon Manganese Alloy 1. Concept: Silicon manganese alloy is an alloy composed of manganese, silicon, iron, and a small amount of carbon and other elements. It is a widely used and high-yield iron alloy. Silicon manganese alloy is a commonly used composite deoxidizer in steelmaking, and also a reducing agent for low-carbon manganese iron and electro silicon thermal production of metallic manganese in production.

Ferrosilicon 65

Silicon iron 65 has always been one of the metallurgical materials purchased by metallurgical material manufacturers. The price of silicon iron 65 is slightly lower than that of silicon iron 75 72, but the silicon content is much better than that of low silicon iron. The national standard silicon iron content is better, and the effect in the metallurgical process is also more obvious. At the same time, the smelting cost is greatly reduced. Therefore, the national standard silicon iron 65 is very popular among metallurgical manufacturers!

High-purity metallic silicon

High purity silicon metal has a higher content of silicon than ordinary silicon metal, usually above 99.9, up to 99.99. The surface of high purity silicon metal is distinctly different from that of silicon metal, and is brighter and smoother than ordinary silicon metal.

Manganese metal

It is also an important alloying element used in the manufacture of stainless steels, high-strength low alloy steels (HSLA), aluminium-manganese alloys and copper-manganese alloys. Manganese metal can be produced industrially and almost all of it is used in the steel industry to make ferromanganese alloys. Manganese ferroalloys can be obtained by reducing the appropriate proportions of iron oxide (Fe₂O₃) and manganese dioxide (MnO₂) with carbon (graphite) in a blast furnace. Pure manganese metal can be produced by electrolysis of manganese sulphate (MnSO₄).

Low carbon ferromanganese

Quality Assurance Delivery Time: Fast delivery within 3-7 days. Samples: Free samples are available. We offer ferromanganese grades for selection. First order discount, contact us now.

Ferrotitanium 30

Ferro Titanium, an intermediate alloy of titanium and iron, is used as a purifying agent for steel. Production process: Ferro-titanium is an alloy of titanium and iron. The process of producing ferrotitanium usually involves mixing titanium and iron feedstocks and reacting them at high temperatures.

Iron Molybdenum 55

FeMo is an iron alloy consisting of molybdenum and iron, generally containing 50-60% molybdenum, and is used as an alloying additive in steelmaking. Ferro Molybdenum is an alloy of molybdenum and iron. Its main use is as a molybdenum additive in steelmaking. Adding molybdenum to steel gives it a uniform fine grain organisation, improves its hardenability, helps eliminate temper brittleness, and alloys with special physical properties. Adding molybdenum to cast iron improves its strength and wear resistance.

Manganese Ore

Manganese ore is an important metallic mineral, primarily used in the steel industry (accounting for about 90%), where it can improve the strength and wear resistance of steel. It is also widely used in new energy batteries, chemicals, non-ferrous alloys, building materials, and environmentally friendly agriculture.

Ferroniobium 50

Ferro Niobium is a ferrous alloy consisting mainly of Niobium and Iron. It also contains impurities such as aluminium, silicon, carbon, sulphur and phosphorus. Depending on the niobium content of the alloy, it can be classified as FeNb50, FeNb60 and FeNb70. ferroalloys produced from columbite-tantalite ore contain tantalum and are called columbite-tantalum.

Ferrovanadium40

Ferrovanadium is a ferroalloy obtained by reducing vanadium pentoxide with carbon in an electric furnace, or by reducing vanadium pentoxide in an electric furnace by the silicothermal method.

Read more

+

year

International market service experience

+

㎡

Building area

+

people

Technical team

Abundant supply

Xuan Yi New Materials (Qingdao) Co., Ltd. has a diversified product range and can provide buyers with a wealth of choices to meet different purchasing needs.

Diversified peripheral categories

In addition to smelting materials, we can also provide related peripheral categories to provide buyers with one-stop purchasing solutions and simplify the purchasing process.

Fast delivery

We focus on delivery speed and can quickly fulfill buyers' orders to ensure that their production and operations are not delayed.

Customizable services

We offer a customization service, producing materials according to the specific needs of buyers to ensure full compliance with their requirements and specifications.

Stable supply

Xuan Yi New Materials (Qingdao) Co., Ltd. is a large-scale mineral enterprise with stable production capacity, ensuring continuous supply to end customers.

High-quality products

We are ISO certified to ensure high-quality products, allowing end customers to obtain reliable materials and improve production efficiency and product quality.

Various customization options

End customers can choose customized products according to their specific needs to ensure that the products fully meet their application requirements.

Technical support

Our team has rich experience and can provide technical support and solutions to end customers, ensuring optimal product performance.

Read more